Derived from the Greek “Enplastron” and Roman “Emplastrum“, Plaster is a building material used for the protective and/or decorative coating of walls and ceilings, and molding and casting decorative elements.

Image source:https://search.creativecommons.org/photos/241b1bc2-a364-4931-b34f-1727ccec70fb by archer10 (Dennis)

Types of Plaster

The most common types of plaster mainly contain gypsum, lime, or cement, but they all work similarly. The plaster produced as a dry powder is then mixed with water to form a stiff but workable paste before being applied to the surface. The reaction with water releases heat by crystallization and the hydrated plaster hardens. Gypsum plaster, or Plaster of Paris, is the most recognized name for plaster casting. Different types of gypsum can be used for a variety of casting.

Origins of Gypsum Plaster

Plaster of Paris got its name due to a large gypsum deposit at Montmartre in Paris. In the 1700s, the king of France ordered that every wooden building be coated in plaster to provide a fire deterrent. Gypsum plaster was used as early as ancient Egypt, according to “A Brief History of Plaster and Gypsum.”

Image source: https://en.wikipedia.org/wiki/Plaster

Image source: https://search.creativecommons.org/photos/36832727-bb7b-40de-b698-0b83e3b04c91 by Palazzo Isnello

How is it Composed?

The plaster of Paris consists of gypsum, a natural mineral of hydrated calcium sulfate with the molecular formula CaSO4·2H2O. This is the most common sulfate mineral. Usually, the color of the crystal is white or colorless but can also have other shades such as gray, red, or yellow, the crystals can also be transparent or translucent. Gypsum is a soft crystal, which can be scratched even by a fingernail, it is flexible, and its thermal conductivity is low.

This material consists of calcium sulfate which is derived from gypsum. Extreme heat evaporates the water from the plaster and creates a fine powder. When the powder mixes with water, it produces a cement-like material. Gypsum plaster is produced by heating the gypsum to about 150 °C:

CaSO4·2H2O + heat → CaSO4·0.5H2O + 1.5H2O (released as vapor).

The chemical reaction that occurs when plaster is mixed with water is exothermic. When the plaster hardens, it can reach temperatures above 60 °C. When dry gypsum powder is mixed with water, it reforms into gypsum. The setting of the unmodified plaster begins about 10 minutes after mixing and is completed in about 45 minutes, but not completely up to 72 hours.

Image source: https://search.creativecommons.org/photos/c82c7642-b55d-4f31-a774-e36c028c5a1e by subarcticmike

How is it Used?

Gypsum plasters have been used for centuries in the construction industry, due to their excellent and unique properties. Provides excellent thermal and acoustic properties by providing wavy lines and level walls with a superior finish.

Image source:https://search.creativecommons.org/photos/bf5ee431-8105-4b6c-a0d6-f8861ec681a4 by Dominic’s pics

It is commonly used for the prefabrication and conservation of load-bearing parts of ornamental plaster placed on ceilings and frames. It is also used medicinally to make plaster casts to immobilize broken bones as they heal, although many modern orthopedic casts are made of fiberglass or thermoplastics.

Image source: https://search.creativecommons.org/photos/2aa01223-8f91-4852-8cf8-4f787d85c13a by ☺ Lee J Haywood

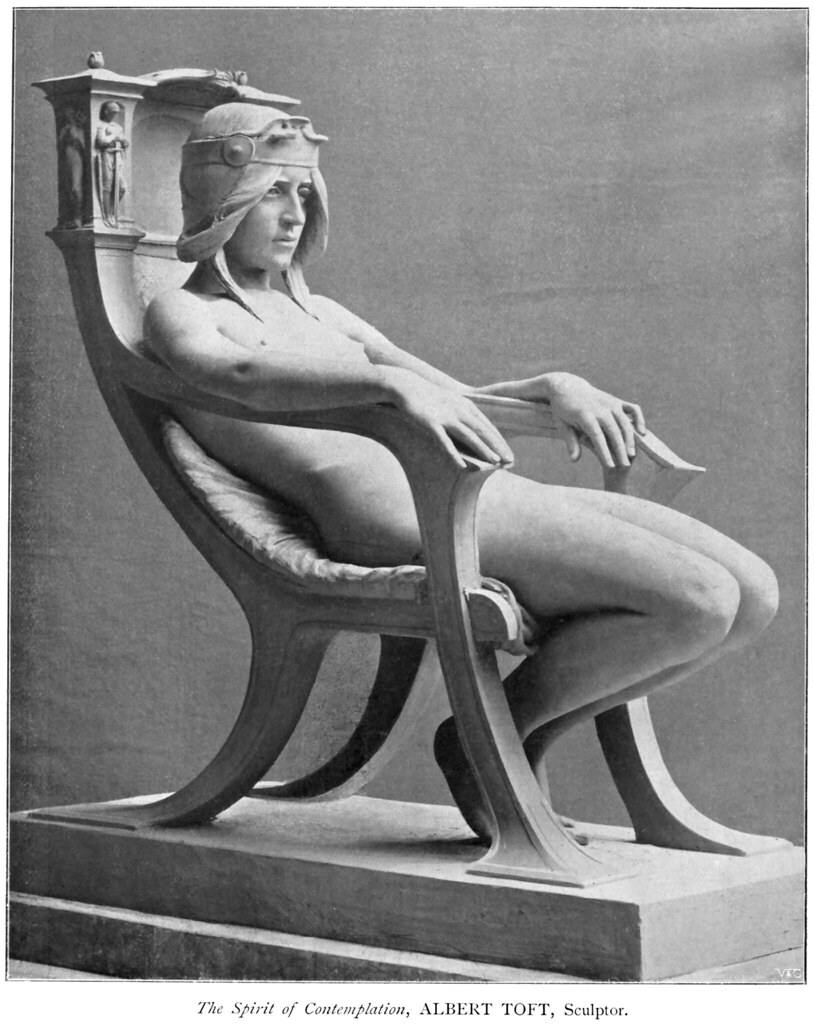

Some sculptors work directly in plaster of Paris, as the speed with which the plaster sets gives the work a sense of immediacy and allows the sculptor to quickly realize the original idea. In medieval and Renaissance times, gypsum (usually made of plaster of Paris mixed with glue) was applied to panels of wood, plaster, stone, or canvas to provide the ground for tempera and oil painting.

Image source: https://search.creativecommons.org/photos/1b38c75e-a895-4e02-9647-b481e8bc3535 by ketrin1407

Info source:

https://en.wikipedia.org/wiki/Plaster

https://sciencing.com/difference-casting-plaster-plaster-paris-6557743.html

http://www.differencebetween.com/difference-between-gypsum-and-vs-plaster-of-paris/